Quality control is a crucial aspect within the production chain, essential for ensuring the integrity and reliability of products. In international production processes, where diverse cultures, languages and standards come together, quality control plays a key role in bridging the gap between expectation and reality. In this blog we will tell you more about the quality control landscape, from the initial concept phase to the final product. We delve into the methodologies, challenges and best practices involved in maintaining quality standards in various production environments, with a special focus on the sourcing process in Asia.

The art of quality

Quality control is often mentioned, but its full meaning is not always clear. It's more than just checking off items on a list. It is a careful process that focuses on attention, precision, and a thorough understanding of quality. This process starts with the first design and continues well after delivery to the customer. Quality control is an ongoing dialogue between the designer, the manufacturer and the consumer, and symbolizes the promise of reliability and customer satisfaction. It plays a crucial role in maintaining customer trust and brand integrity.

What exactly does a quality inspector do?

A quality inspector, also known as a quality manager or quality inspector, is responsible for closely examining products, materials and production processes to ensure that they meet established standards and specifications. They perform visual inspections, measure products for accuracy, check materials for quality and follow strict procedures to detect any deviations. Their job is to ensure that every product that leaves the factory is perfect and meets customer expectations. Quality inspectors play an essential role in ensuring the integrity of a brand and maintaining high standards of product quality.

Read more:

What is Private Label? - Importing our own brand from Asia

In this blog we delve deeper into the concept of private label imports from Asia, its benefits for your business, and essential considerations for successfully implementing this strategy.

What types of inspections are there?

At Westwood Sourcing we take quality auditing very seriously and offer a wide range of product checks and inspections to ensure the integrity of your products. From the very first production we offer the 'First Article Check', where we check the first product exemplarily to ensure that the production meets the set standards. During the production process we carry out 'During Production Checks' to ensure continuity in quality and to intervene in a timely manner if necessary. Before shipment, products undergo a 'Pre-Shipment Inspection' or 'Final Random Inspection' to confirm that the entire batch meets the requirements. Furthermore, with the 'Container Loading Check' or 'Loading Supervision' we ensure that the goods are loaded correctly and safely for transport. Finally, we conduct 'Factory Audits' to assess production facilities and ensure they meet our strict standards for quality and sustainability. Each of these steps is crucial to ensure that the products we source not only meet the expectations of our customers, but also contribute to a responsible and sustainable production chain.

Quality control checklist

To ensure that all products from Asia from Westwood Sourcing customers meet our high standards, we apply the following quality control checklist:

- Material verification

- Compliance with specifications- Quality and durability of the material - Design check

- Compliance with design specifications- Aesthetic inspection and finishing - Functional tests

- Efficacy and performance under standard conditions of use- Lifespan and reliability testing - Packaging inspection

- Suitability and strength of the packaging- Correct labeling and barcodes - Craftsmanship

- Accuracy and consistency in production- Absence of defects and damage - Security checks

- Comply with international safety standards- Check for harmful substances and materials - Regulation and certification

- Compliance with local and international regulations- Availability of required certificates - Environmental impact

- Assessment of the environmental friendliness of the production process- Sustainable use of materials and resources

This checklist is strictly followed at every step of the sourcing process to ensure that the products not only meet our customers' expectations, but also reflect our commitment to ethical and sustainable business practices.

Read more:

Sourcing in China: Your guide to successful procurement in China

With its vast production capacity, wide range of industries and favorable prices, China remains one of the most attractive markets for sourcing. This article is intended to guide companies in sourcing efficiently and successfully in China.

Most common errors during quality checks

Quality checks sometimes introduce errors that can undermine the entire process. Some of the most common mistakes are:

- Insufficient specifications:

Not clearly defined or incomplete specifications lead to confusion and inconsistencies in the final product. - Communication deficiencies:

Inadequate communication between the different departments can lead to misunderstandings and errors in the production process. - Overreliance on sampling:

Too small a sample size can result in overlooking crucial flaws. - Ignoring feedback:

Not taking feedback from customers or the production floor seriously or ignoring it can lead to repeated mistakes. - Outdated procedures:

Adhering to outdated quality control procedures can be inefficient and make error detection more difficult. - Insufficient training:

Employees who are not properly trained in quality control practices may miss critical defects. - Lack of continuous improvement:

Failure to continuously evaluate and improve the quality control process can lead to stagnation and reduced product quality.

Read more:

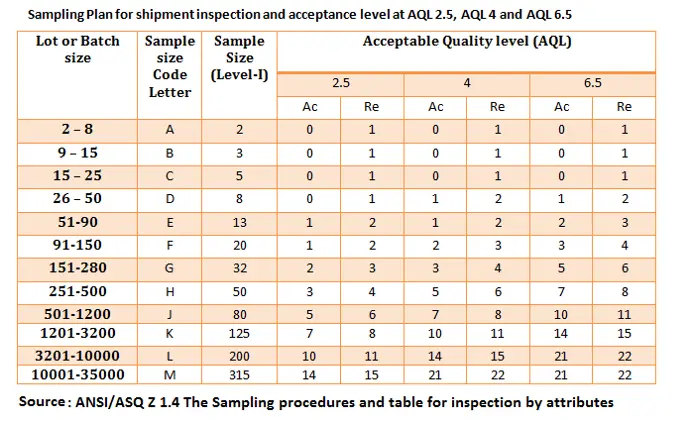

What is AQL?

In this blog we take a closer look at what AQL means, how it is applied, and why it is so important for quality control.

The costs of quality control: investment or expense?

When considering quality control, the question often arises: what is the cost and is it worth it? It's important to understand that quality control is an investment in the future of your business. Yes, there are costs associated with implementing rigorous quality procedures, such as hiring qualified inspectors, purchasing technological equipment and conducting tests. However, the long-term benefits far outweigh these initial costs. Through quality control you minimize the risk of production errors and defects that would otherwise lead to expensive recalls and complaints. Furthermore, it helps maintain a positive reputation and earn customer trust, which in turn leads to greater sales and growth.

How we can help

At Westwood Sourcing we understand the challenges of maintaining the highest quality standards. Our team of experts is ready to meet and overcome these challenges together with you. With our in-depth knowledge and experience in quality controls in China and Vietnam, for example, we offer a range of services designed to optimize every aspect of your production process. This way we can not only take care of quality control, but also the entire sourcing. Together we ensure that your products not only meet expectations, but exceed them time and time again.

Do you need help with quality control in China?

Contact us to discuss the possibilities!